Overview

Inquiry

Related Products

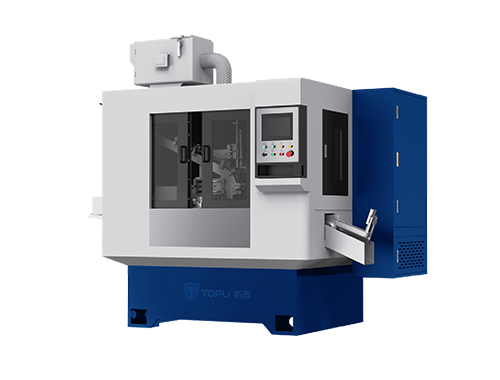

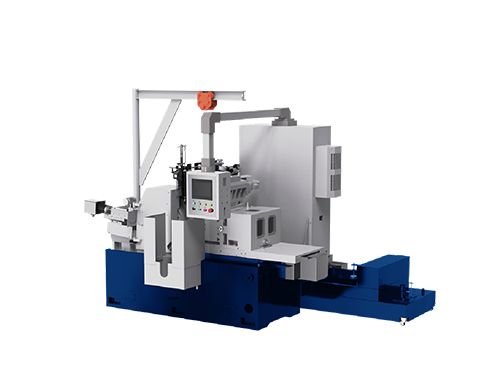

Introduction

Centerless grinding machine is suitable for coarse grinding, semi-fine grinding and fine grinding valve rod. This high precision centerless mill has a total of 5 axes, equipped with automatic loading and unloading mechanism, changing different grinding wheels to achieve different precision grinding.

Machine structure and performance

1) The front and back supports of the grinding wheel spindle are all bearing structures with high rotation accuracy. Ac frequency converter is used to control the motor to realize automatic segmented speed change, so as to achieve constant line speed. Maximum line speed of grinding wheel 45m/s;

2) Guide wheel spindle: guide wheel front and rear support with integral sliding bearing with inner cone of 1:10; The rear support adopts pairs of double angular contact ball bearings for radial positioning and axial positioning, and then adopts aligning ball bearings for auxiliary support, which has good stiffness. Ac frequency converter is used to control the motor to achieve stepless speed change, and the working speed is stable and reliable.

3) The feed of the guide wheel frame is driven by the servo motor and the ball screw to achieve fast and slow feed and micro-compensation. The feed guide adopts double V-type needle roller guide, with sensitive feed and good rigidity. Reciprocating positioning accuracy ≤0.002;

4) Diamond roller dresser: The dresser feed is driven by a servo motor and the ball screw controls the dressing amount and compensation amount. The reciprocating motion is driven by a servo motor and the ball screw can be adjusted stepless. Can complete automatic compensation, counting compensation, synchronous compensation, the minimum compensation amount 0.001. Reciprocating positioning accuracy ≤0.002;

5) The guide wheel dresser adopts manual feed, speed regulating motor drives the dressing movement; Stepless speed regulation;

Specification parameter

| Machining accuracy | Rough grinding(mm) | Semi-finished grinding(mm) | Finishing(mm) | |

| Machining allowance | 0.1-0.15 | 0.03-0.05 | 0.01-0.03 | |

| Roundness | 0.01 | 0.005 | 0.003 | |

| Roughness | Ra1.2 | Ra0.8 | Ra0.3 | |

| Runout | 0.01 | 0.005 | 0.003 | |

| Rod tolerance | ±0.01mm | ±0.005mm | ±0.003mm |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

UK

UK

TR

TR

MS

MS

BE

BE

HY

HY

AZ

AZ

KA

KA

EO

EO

LA

LA

SU

SU

TG

TG

UZ

UZ